Mounting oarlocks in different spots on a vessel requires a sturdy mounting block, capable of working with the stresses that occur from normal operation. Steel pieces offer the greatest strength for the lowest cost, making it the ideal choice for use in this project. Steel construction will be used throughout, from the mounting block, to the bolts and washers used to secure the assembly to the vessel hull. Knowledge of metalworking, specifically, welding, is required for the project’s success. Several holes must be tapped through solid steel, requiring careful attention to detail by the builder. There are two oarlock blocks required for the project, with both sides undergoing construction simultaneously. If both sides are built at the same time, it will be easier to apply similar techniques to both units instead of finishing one before beginning another.

Plan of Procedures:

A. Material Processing Steps:

1. Receive uncut steel flats in 40” size

2. Measure & cut 40”x 3” x ¼” steel flat into two 20” sections

3. Measure & cut 40” x 1.5” x ¼” steel flats into four 20” sections

4. Measure & cut 1” diameter hole into 3” steel flat

i. Measure 2” from end of flat to center of hole

ii. Measure 2” from center of hole, cut second hole

iii. Repeat cuts: four holes from side

5. Measure and cut access hole for stainless steel bolt

i. Measure 10 inches from center

ii. Cut hole wide enough for SS Bolt

6. Measure and cut 1” diameter hole for remainder of flat

i. Measure 2” from center of SS Bolt hole

ii. Cut 1” diameter hole in flat

iii. Repeat cuts: four holes from center

7. Repeat steps 4-6 for second 3” steel flat

B. Assembly Procedures

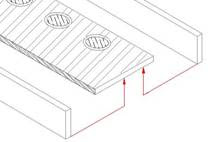

1. Clamp 1.5” steel flat at 0.5” from outside of 3” steel flat

2. Weld 1.5” steel flat into place onto 3” steel flat

3. Clamp 1.5” steel flat at 1.5” from outside of 3” steel flat, opposite of first 1.5” flat

4. Weld second 1.5” steel flat into place onto 3” steel flat

5. Repeat steps 1-4 for second steel flat

6. Mount washer and bolt assembly through bolt hole on steel flat

7. Mount completed oarlock assembly to vessel through existing oarlock hole

8. Secure device to boat with attachment of steel nut to stainless steel bolt

C. Finishing Steps

1. Mount desired oarlocks through holes in steel flat

2. Secure oarlocks to steel flat using existing cotter pin system

3. (if present on chosen oarlock)

No comments:

Post a Comment